.

Mopwringer type SR

• High separation efficiency with minimal water content

• Absorption of low oil film thicknesses possible

• Suitable for explosion protection

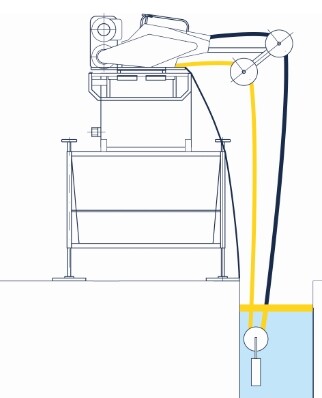

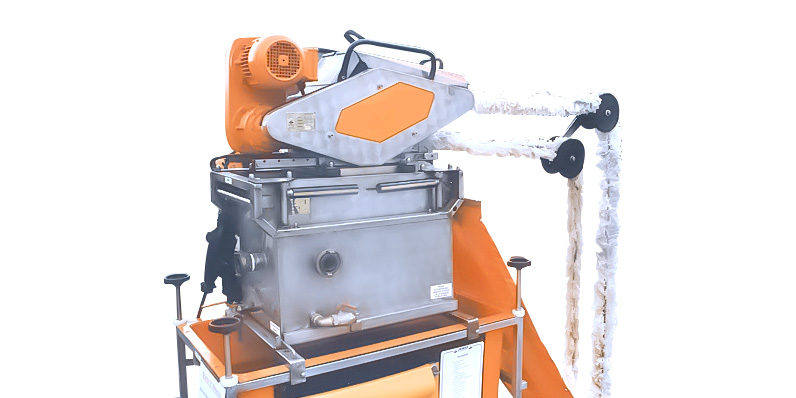

The Mopwringer system essentially consists of two interdependent main components, the drive system and the oil magnetic belt.

The use of the oil magnetic belt is variable; it can be guided vertically and horizontally via deflection rollers.

Hydrocarbons are drawn off the water surface by the belt rotation speed and the adsorption capacity of the oil magnetic belt and pressed out by two special rollers in the adjustable drive system.

The Mopwringer drive system is equipped with an explosion-protected three-phase helical variable speed gear motor, motor protection switch and Ex CEE plug 380 V, 16 A. The drive, the pressure and the drive rollers are made by a toothed sprocket combination.

The roller gap is adjustable via a handwheel. The bearing of the pressure roller in a rocker arm enables the constant oil magnetic belt transport via a spring assembly and ensures the passage of thickenings, knots in the oil magnetic belt, pieces of flotsam, oil binding agents, etc.

The mop wringer is additionally equipped with a driven output roller as well as adjustable infeed rollers, which ensure an oil magnetic belt guidance suitable for use. The continuously lockable holding device enables the use of the vertical oil magnetic tape guide. The wringer hole pattern is compatible for sled, collection tank and separator.

Functional features

- Absorption of thin oil films possible

- Suitable for oil damage control or permanent installation

- Robust & proven design

- Insensitive to foreign particles and clogging, in contrast to weir skimmers

- All relevant components (motor, switch etc.) in ATEX-compliant design

- Simplified power regulation

Mopwringer type SR

| Item no. | |

| POWER | 1400 l/h |

| TECHNICAL DATA WRINGER | |

| WIDTH | 400 mm |

| LENGTH | 900 mm |

| HEIGHT | 480 mm |

| WEIR WIDTH | 920 mm |

| CONNECTION | R 2″ AG, incl. Storz fixed coupling |

| MATERIAL HOUSING/COVER, CHAIN CASE, SHAFTS | V4A, stainless steel 1.4571 |

| UNWIND ROLLERS | Wire mesh V4A – 1.4571 |

| GUIDE ROLLERS | PA (polyamide) |

| SPROCKETS AND CHAIN WHEELS, DRIVE CHAINS | V2A – 1.4301 |

| SHEAR-OFF PROTECTION THROUGH PEN | Ms 58 at 1600 N |

| OIL MAGNETIC TAPE GUIDE | 2-fold |

| BELT SPEED | 0,07 – 0,42 m/s |

| WEIGHT | 100 kg |

| TECHNICAL DATA THREE-PHASE HELICAL VARIABLE SPEED GEARMOTOR | |

| POWER | 1,1 kW |

| VOLTAGE | 380 V |

| FREQUENCY | 50 Hz |

| NOMINAL CURRENT | 2,75 A |

| Rotational speed | 1480 n (min-¹) |

| OUTPUT SPEED | 25 – 150 n (min-¹) |

| TORQUE | 58 Nm |

| ISOLATION CLASS | B |

| PROTECTION CLASS ACCORDING TO DIN 40 050 (IEC 529) | IP 56 |

| EX PROTECTED | EEx e ll T3 |

The performance is based on an oil layer thickness of 10 mm, a belt speed of 0.23 m/s using 2 oil magnetic belts with a width of 160 mm.

Specification of technical data subject to change. Customised design (voltage, power, speed, protection class, etc.) can be implemented.

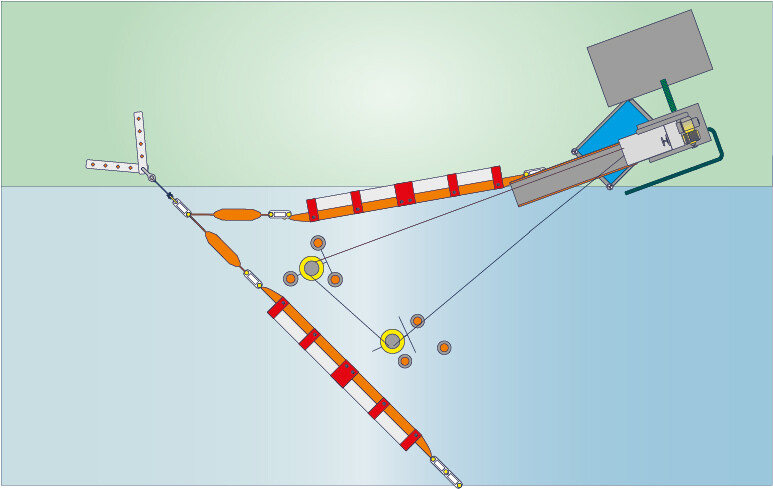

EXAMPLE APPLICATION

Mop wringer type SR with carrying carriage

Content Here

Separator

Content Here

Free water drain

Content Here

Pedestal box

Scaffolding container 3000 l

Oil magnetic tape

Idler pulleys

Application example Mopwringer compact unit type SR

Matching products

Pumps

Oil separator

Collecting tank

Complete Solution